Ergonomically Designed Tools for Garment Industry

Shafiun Nahar Elma

Industrial & Production Engineer

National Institute of Textile Engineering & Research (NITER), Bangladesh.

Email: [email protected]

The garments sector continues to play an influential role in the economic development of the world, it employs millions of people across global and earns substantial export earnings. It is, however, an industry that is well-known for putting a great deal of pressure on its employees by exposing them to repetitive work, physical stress, and awkward postures. That use of appropriate tools to accommodate the garments sector best be described as a revolution in enhanced welfare for workers as well as an enhancement of productivity. In this article, the author focuses on the new developments in ergonomically designed tools, statistical information from 2024, and the tremendous influence on the garments industry.

Ergonomically Designed Tools Uses in Garment Industry:

Ergonomics is the science of understanding tools and the workplace’s physical constraints to eliminate pain and the risk of damage. Workers in the garment sub-sector typically spend long hours each day performing boring tasks such as stitching, cutting, and garment finishing; hence, ergonomics plays an important role in preventing workload-related stress, which leads to MSDs. Appropriate instruments for use in the garment industry not only boost production rates but also keep personnel healthy and happy.

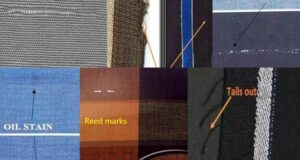

Improved Quality of Work: Pleasant working conditions and product quality have always been healthy for one another. When garment workers can ergonomic tools, they can alleviate distractions and reduce errors in the garments they are producing.

Reduction in Worker Absenteeism: Injuries are one of the main reasons for sick leaves among employees in the garments sector. When companies adopt ergonomic solutions, they realize a dramatic reduction in terms of lost work days due to injuries and employee turnover rates.

Machine Tool Related Ergonomics in Garments Industry:

1. Bluetooth sewing machines

Sensors are now placed on the worker’s body and the whole height and tilt angle of the machine will come down automatically. This Personal Construct Feedback system avoids slouching and exercises positive pressure for better postures to avoid further exertion on the neck and shoulders. These ergonomically designed tools give the worker relief from different health problems.

2. Organized height-adjustable cutting tables

The new models of 2024 consist of ergonomically designed heights and tilting that the workers can vary according to their preferences. They reduce cases of back and neck injuries and design the working environment to suit the worker.

3. Ergonomically designed tools & comfortable hand equipment

Scissors, rotary cutters, and others are critical tools that are used during garment production but using them by hand puts more pressure on the hands. Creative manufacturers came up with lightweight and ergonomic hand tools that allow for a better grip, and equal force distribution thereby eliminating carpal tunnel diseases.

4. Wearable ergonomics devices

Smart clothing technology is helping the actual wearers of garments for work to adopt better standing positions and practices. Other wearables include smart belts and other posture-correcting sensors that provide the worker with the status of his body postures in a manner.

5. Anti-fatigue ergonomic mats

These ergonomic anti-fatigue mats, with cushioned surface designs, provide physical comfort to employees while standing for long hours continuously and thus reduce the probability of aching legs and lower back pains.

Impact of Ergonomically Designed Tools for the Garments Sector:

A recent survey conducted in 2024 showed that 65% of garment manufacturers all over the world have started investing in ergonomic tools. One of the advantages of fewer injuries is reduced healthcare costs.

The year 2024 has witnessed significant technological advancements in the garment business in terms of ergonomically designed devices. These innovations have not only worker comfort but also increased efficiency.

Companies that implemented ergonomic solutions on assembly lines reported a 42% reduction in work-related injuries, especially musculoskeletal disorders, during the first year of implementation.

Employee satisfaction increased by 37% and product efficiency increased by more than 20% after using ergonomically designed tools. This indicates that comfort and safety are directly related to job satisfaction.

Upcoming Trends in Garments Marketplace Ergonomically Designed Tool Conception:

- Use of Artificial Intelligence: Incorporating AI into ergonomics will be revolutionary for the industry. It’s the first time that AI-based tools can observe worker movements in time. They then provide suggestions on adjusting tools or workstations. It will also reduce workplace injuries.

- Emphasis on Green & Sustainability: Concerns regarding environmental friendliness and sustainability will become increasingly important in each area. Even in the garment sector. Perhaps in the future, ergonomically designed tools or gadgets will have eco-friendly components. This enables Tools to function by sustainable principles.

- 3D Printing for Customization: 3D printing is becoming increasingly accessible. As a result, it is simple to create customized ergonomically designed tools for the apparel industry. These instruments are specifically created to meet the needs of each worker.

- Ergonomic Training for VR: Ergonomically designed tools are more complex and combine with advanced technology. To teach employees how to use tools properly, virtual reality training programs are being developed.

- Pattern Making: To make fit clothing, designers want a 3D avatar that closely resembles real body shapes. AUDACES, ergonomically designed tools invented by an Italian-Brazilian corporation, considered this issue when producing goods. Audaces has been active in various areas of the fashion industry for over three decades, offering a pattern plotter, fabric layer spreader, pattern conveyor cutter, and a wide range of software that are required for all garment, fashion, technical clothing, and upholstery productions, among other technologies.

- Customized Mannequins: CAD Modelling, founded in Italy, focuses on fit, safety, and ergonomic gear. It created its tailor mannequin concept to improve fit in the garments business. At the same time, it has developed technology and ergonomically designed for mannequin production that sustainably saves time and resources.

Conclusion:

When scientifically engineered ergonomic equipment for the garment industry first appeared, it was a watershed moment in development history. Not only can these products improve workers’ comfort and health, but they also increase productivity, minimize injuries, and lead to higher job satisfaction. Nowadays, the adoption of ergonomic tools is expected to continue because of innovations in AI, sustainability, and customization. Ergonomically designed tools for the garments sector will continue to lead from the front with industrial development for a considerable period, a more productive, and worker-friendly industrial environment.

References:

- https://textilelearner.net/ergonomics-in-fashion-design-application-and-importance/

- https://www.researchgate.net/publication/320322250_Ergonomic_to_Design_Safe_and_Comfort_Work_Stations_for_Garment_Workers_Bangladesh_Perspective

- https://www.sciencedirect.com/bookseries/elsevier-ergonomics-book-series

- https://apparelresources.com/business-news/manufacturing/ergonomics-in-apparel-manufacturing-ii/

- https://apparelresources.com/business-news/manufacturing/ergonomics-in-apparel-manufacturing-i/

- https://www.textileschool.com/7727/ergonomic-improvements-in-textile-industry/

Founder & Editor of Textile Learner. He is a Textile Consultant, Blogger & Entrepreneur. He is working as a textile consultant in several local and international companies. He is also a contributor of Wikipedia.